In the realm of CNC (Computer Numerical Control) machining, the turret plays a crucial role in holding and indexing the cutting tools required for precision machining operations. Different types of CNC turrets are available, each offering unique features and capabilities to meet the diverse needs of manufacturers.

Single-Station Turrets:

Single-station turrets, also known as fixed turrets, are the simplest type of turret used in CNC machining centers. These turrets hold a single cutting tool at a fixed position, and the tool change process involves manually swapping out tools when necessary. Single-station turrets are commonly found in small-scale machining operations or applications where tool changes are infrequent.

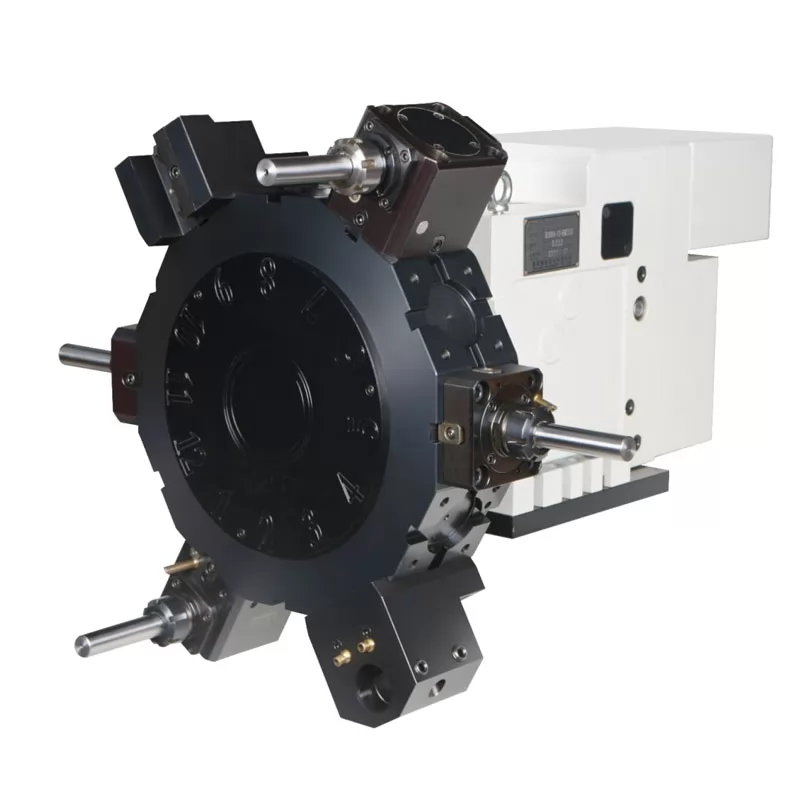

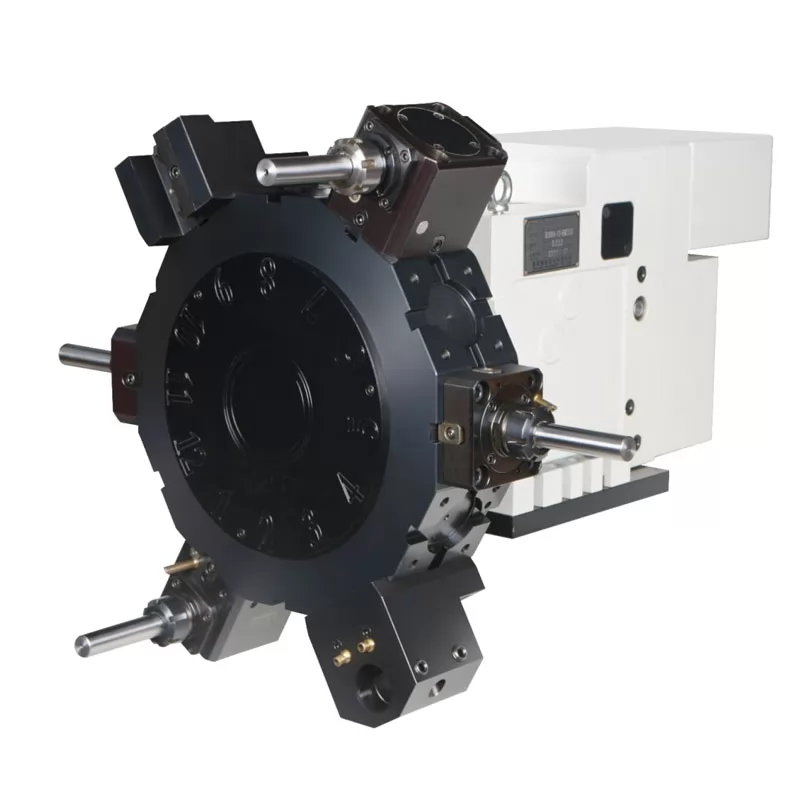

Drum Turrets:

Drum turrets, also known as disc turrets, feature multiple tool stations arranged in a circular drum or disc configuration. Each tool station holds a cutting tool, and the turret rotates to index the desired tool into the machining position. Drum turrets offer faster tool change times compared to single-station turrets, making them suitable for applications requiring multiple tooling setups and shorter cycle times.

Capstan Turrets:

Capstan turrets are a variation of drum turrets commonly used in CNC turning centers. Unlike traditional drum turrets, which index tools in a radial direction, capstan turrets index tools in a linear or axial direction. This design allows for rapid tool changes and reduced indexing times, making capstan turrets well-suited for high-speed turning operations with a large number of tool changes.

Gang Turrets:

Gang turrets, also known as gang tooling systems, consist of multiple tool holders mounted in a linear configuration along the turret axis. Each tool holder holds a cutting tool, and the entire gang turret moves together to position the desired tool for machining. Gang turrets are commonly used in CNC lathes and Swiss-type turning machines, where space constraints necessitate compact tooling setups and high-speed machining capabilities.

See also:

Mechanical Parts & Fabrication Services

What are the different types of conveyor bearings used in industrial applications?

How does a submersible slurry pump work?

What are the benefits of Photocatalyst Filters in air purification?

Top Trends in Cast Aluminum Patio Furniture Design

What Factors Can Affect Spring Life?

Smooth Sailing with Three-Blade PropellersHybrid Turrets:

Hybrid turrets combine the features of drum turrets and gang turrets to provide a versatile tooling solution for CNC machining centers. These turrets feature a combination of rotating tool stations and linear tool holders, allowing for both radial and axial tool changes. Hybrid turrets offer the flexibility to accommodate a wide range of cutting tools and machining processes, making them ideal for complex machining operations requiring multiple tooling configurations.

The choice of CNC turret depends on factors such as the type of machining operation, the complexity of the workpiece, and production requirements. By understanding the different types of CNC turrets available, manufacturers can select the most suitable turret design to optimize machining efficiency, tool change times, and overall productivity in their operations.

Related articles:What are the key components of an AH Slurry Pump?Which Air Purifiers Use Photocatalyst Filters?What is a Nipple Drinker and How Does It Work?How does a hydraulic directional control valves work?Key Questions and Answers About Auto Coil SpringsPower Chuck Vs Manual Chuck For WorkholdingThe role of ball bearing lubrication and the method of oil lubrication

Comments

0Related Articles

By May

100

0

0

By May

95

0

0

By Hou

90

0

0

By Hou

129

0

0

By CC

166

0

0

By May

91

0

0

By CC

49

0

0

By Hou

49

0

0