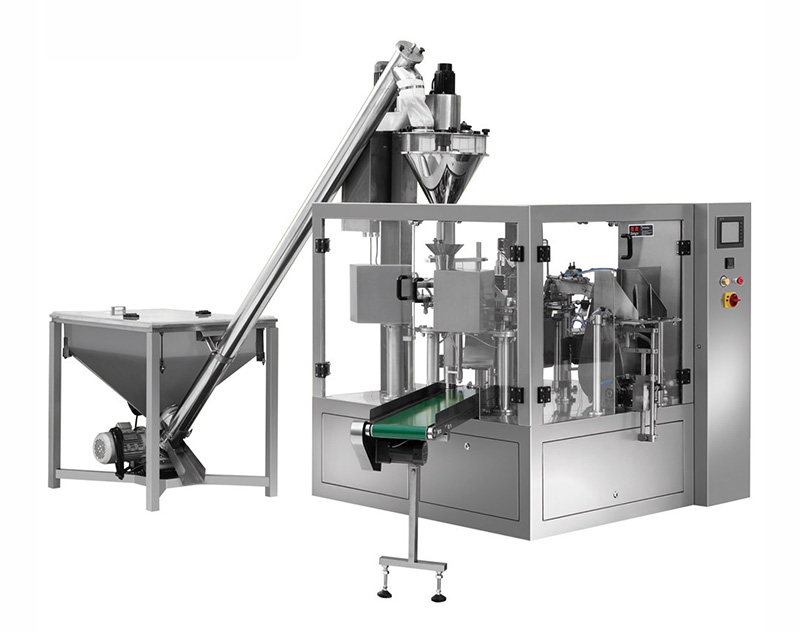

A stand-up pouch filling machine is a specialized equipment designed for efficiently filling and sealing stand-up pouches with various types of products, ranging from liquids to powders. The machine undergoes a systematic process to ensure accurate and hygienic packaging. Here's an overview of how a stand-up pouch filling machine works:

1. Pouch Loading: The process begins with the loading of empty stand-up pouches into the machine. These pouches are typically pre-formed and positioned on a rotary or linear conveyor system, ready to undergo the subsequent filling and sealing operations.

2. Pouch Opening: The stand-up pouches are opened to create a wide mouth for product filling. Various mechanisms, such as vacuum or air pressure, may be employed to ensure that the pouches are opened consistently and without distortion.

3. Product Filling: The machine accurately dispenses the product into the open pouches. Depending on the type of product, filling can be achieved through auger fillers, piston fillers, volumetric fillers, or other specialized filling mechanisms. Precise measurement ensures that each pouch receives the correct amount of product.

4. Sealing Mechanism: Once filled, the stand-up pouches move to the sealing station. The sealing mechanism is crucial for maintaining product freshness and preventing contamination. Heat sealing is a common method, where the top of the pouch is heated to create a secure, airtight seal.

5. Additional Features: Some pouch filling machines may incorporate additional features, such as date coding or labeling, to provide essential information like expiration dates or batch numbers on the pouches.

See also:MachineryWhat is the use of stretch wrapping machine?Guide to Automatic Riveting MachineTop Trends in Automatic Wire Straightening: What You Need to Know for 2024What is shaft forging?The Significance of Drill Pipe Thread ProtectorsWhat is the DTH method of drilling?6. Optional Rinse and Clean: In situations where hygiene is paramount, some machines include a rinsing or cleaning station to ensure that the pouches are free from contaminants before filling. This step is particularly important in industries like food and pharmaceuticals.

7. Inspection and Quality Control: After sealing, the filled pouches may pass through an inspection system that checks for proper seal integrity, correct fill levels, and any defects. This ensures that only high-quality and accurately filled pouches proceed to the final packaging stage.

8. Discharge and Packaging: The filled and sealed stand-up pouches are then discharged from the machine onto a conveyor belt or packaging line. Depending on the production setup, additional processes such as cartoning or case packing may be integrated for further automation.

9. User Interface and Control System: Stand-up pouch filling machines often feature a user-friendly interface and control system. Operators can monitor and adjust parameters such as fill volumes, sealing temperatures, and production speeds through a centralized control panel.

10. Efficiency and Speed: These automatic pouch filling machines are designed for high-speed and efficient operation, with some models capable of filling and sealing hundreds of pouches per minute. This efficiency is crucial for meeting the demands of large-scale production.

In summary, a stand-up pouch filling machine streamlines the packaging process by automating the loading, filling, sealing, and quality control of stand-up pouches. Its versatility makes it suitable for a wide range of products and industries, enhancing production efficiency and ensuring the integrity of packaged goods.

Related articles:What are the different types of RC drilling rig?What are aerial telescopic boom aerial work platforms used for?Advantages of Sheet Metal Laser Cutting MachineWhich is Better for Clearing Land, an Excavator or a Bulldozer?What is the difference between induction motor and slip ring motor?The Ultimate Buyer's Guide for Purchasing Bucking MachinesHow to Maintain foam molding machine

Comments

0Related Articles

By Hou

57

0

0

By CC

161

0

0

By Hou

118

0

0

By Hou

118

0

0

By Hou

54

0

0

By CC

172

0

0

By CC

49

0

0

By Hou

152

0

0