In the world of protective films, two prominent materials are often compared and sought after for their diverse applications and performance capabilities - PE (Polyethylene) Protective Film and PET (Polyethylene Terephthalate) Protective Film. As industry-leading experts in protective films, we aim to provide you with a comprehensive comparison of these two materials, highlighting their differences, advantages, and best use cases. This article aims to be your ultimate guide to understand the unique characteristics of each film, assisting you in making informed decisions for your specific protective needs.

1. Composition and Material Properties

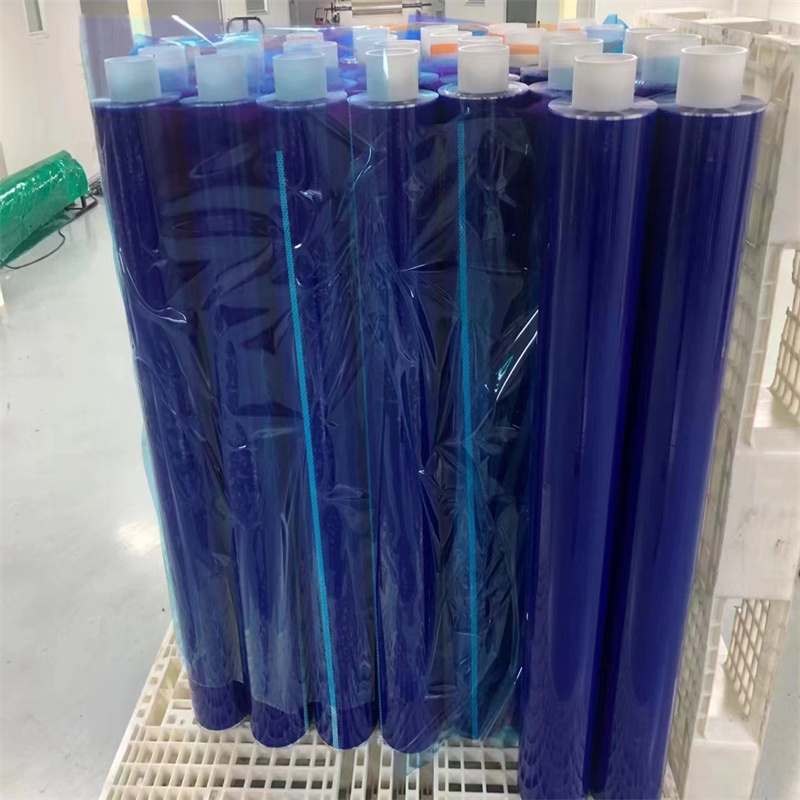

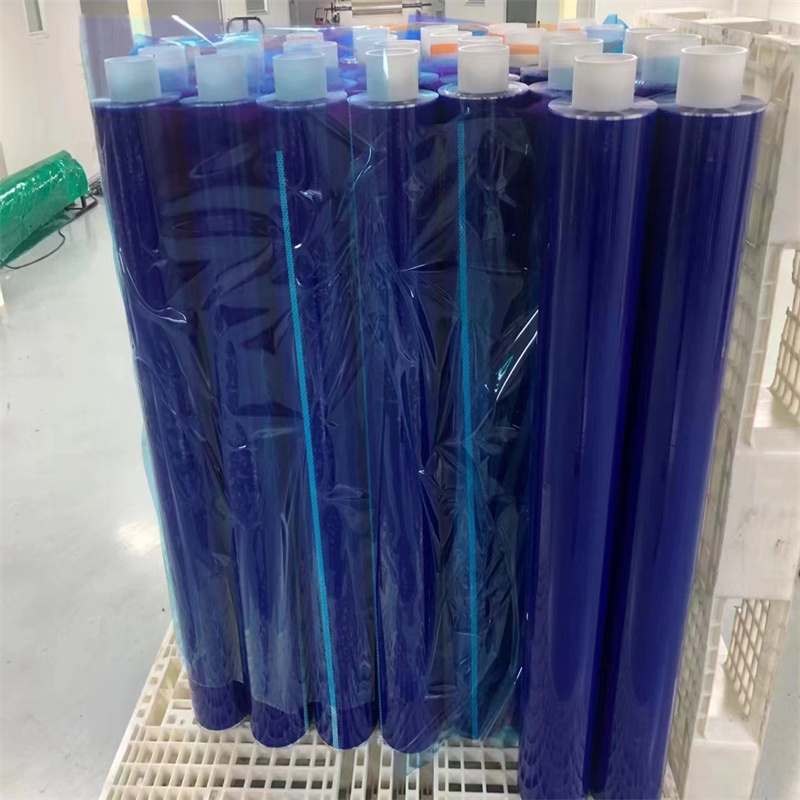

PE Protective Film is made from Polyethylene, a thermoplastic polymer known for its excellent flexibility and moisture resistance. On the other hand, PET Protective Film is composed of Polyethylene Terephthalate, a durable and high-tensile strength polymer that offers superior optical clarity and abrasion resistance.

2. Adhesive Strength

Both films are equipped with adhesive layers to securely bond to the surface they protect. PE Protective Film generally has a lower adhesive strength compared to PET Protective Film, making it easier to remove without leaving any residue. PET Protective Film, with its stronger adhesive properties, provides enhanced adhesion to various surfaces, making it ideal for long-term applications.

3. Surface Protection

PE Protective Film is commonly used for protecting sensitive surfaces during handling, transportation, and installation. Its moderate adhesive strength ensures easy removal without damaging the surface. On the other hand, PET Protective Film is often preferred for high-value items and electronic displays, where optimal protection against scratches, abrasions, and UV exposure is crucial.

4. Clarity and Transparency

PET Protective Film exhibits exceptional optical clarity and transparency, making it an excellent choice for applications where maintaining the original appearance of the surface is essential. PE Protective Film, while providing sufficient transparency, may not match the crystal-clear visibility offered by PET.

5. Outdoor Durability

Due to its superior UV resistance, PET Protective Film is a preferred choice for outdoor applications, as it can withstand prolonged exposure to sunlight without yellowing or degrading. PE Protective Film, while suitable for short-term outdoor use, may not offer the same level of longevity as PET.

6. Strength and Tear Resistance

PET Protective Film boasts remarkable strength and tear resistance, providing reliable protection against impact and harsh handling. For applications that demand robust protection, PET is often the material of choice. PE Protective Film, while flexible, may not provide the same level of tear resistance as PET.

7. Eco-Friendliness

PE Protective Film is generally considered more eco-friendly as it can be recycled more easily compared to PET. This aspect may be crucial for companies with a focus on sustainability and environmental responsibility.

8. Cost Considerations

PE Protective Film is usually more cost-effective compared to PET Protective Film, making it a preferred option for applications with budget constraints. PET, being a higher-end material, may come at a premium cost.

Conclusion

In conclusion, both PE and PET Protective Films offer distinct advantages, and the choice between them depends on the specific needs of your application. PE Protective Film excels in its ease of removal, surface protection, and eco-friendliness, making it ideal for short-term and cost-sensitive applications. On the other hand, PET Protective Film stands out with its exceptional clarity, outdoor durability, and tear resistance, making it the go-to choice for long-term and high-value applications.

When selecting the right protective film for your project, carefully assess your requirements and consider factors such as adhesive strength, surface protection needs, outdoor exposure, and budget considerations. By doing so, you can make an informed decision and ensure the utmost protection for your valuable surfaces and products.

Comments

0